WHAT ARE YOU LOOKING FOR?

NAT provides metal processing services and offers a range of techniques to manipulate metal into desired shapes and structures. Our metal processing services include irregular shape drawing, punching, bending, and welding, which allow for a wide range of products, from small, intricate parts to large, complex structures.

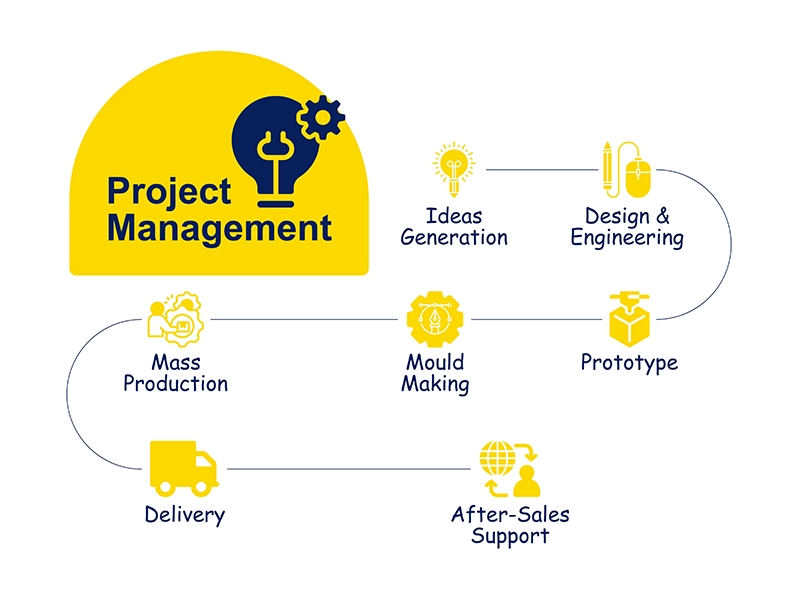

We turn a customer's idea into a tangble product! Just provide your initial idea or concept for the product you want to create, then our team will work on the detailed and technical designs. A mould will be built and mass production goods will be delivered to you soon!

Here's a general outline of how this process might work:

Idea Generation: The customer provides their initial idea or concept for the product they want to create.

Design& Engineering: The design team takes the customer's idea and turns it into a detailed design. This might involve creating 3D models. The design will take into account factors like the product's intended use, the materials it will be made from, and the manufacturing processes that will be used. The engineering team takes the design and works out the technical details. They will determine the exact specifications for the product, and create the detailed plans that will be used in the manufacturing process.

Prototype: A prototype will be made to be presented to the customer for approval. The customer can see the physical realization of their idea and provide feedback or request changes before the product goes into full production.

Mould Making: Based on the design and engineering plans, a mould is created. This mould will be used in the manufacturing process to shape the product.

Mass Production: Once the mould is ready, mass production begins. The product is manufactured, inspected for quality, and then packaged for delivery.

Delivery: The finished products are delivered to the customer.

After Sales: NAT, as a professional pedal car maker, provides technical support and warranty agreement to customers after the products have been delivered. The factory also collects feedback from the customers about the product and uses this to make improvements in future versions.

Throughout this process, the project manager is responsible for ensuring that everything stays on schedule and within budget. They will coordinate between the different teams, solve any problems that arise, and communicate with the customer to keep them updated on the progress of their product.